Facilities Management

- Administration and Finance

- Facilities Management

- CUPR

- Building Systems

Building Systems (Internal)

As a result of the CUPR project, many buildings on campus have benefitted from additional energy conservation measures that maximize savings and energy efficiency. These measures decrease reliance on fossil fuels and improve occupancy comfort and performance by creating healthier spaces.

LED lighting was installed in 24 campus buildings as part of the CUPR project, improving lighting quality, providing exceptional user control, and using available daylight to reduce energy consumption. This has enhanced the learning and working environment for Fresno State students, faculty, and staff. It has also reduced deferred maintenance. The lighting upgrades included:

- 15,264 fixtures retrofitted/replaced

- 9,391 fixtures with new occupancy/daylight sensors

- Wireless controls that deliver enhanced energy management and flexibility and reduce

energy use through:

- Task tuning: optimizing the overall lighting levels

- Wireless occupancy controls: sensors detect motion to control room lighting; if the space is determined to be unoccupied, the lights are wirelessly switched off

- Wireless daylight harvesting: sensors detect natural light levels then wirelessly dim or switch off lights to conserve energy

- Zoning: groups of lighting fixtures are controlled independently

Before

Fresno State classroom with old lighting.

After

Fresno State classroom with newly installed LED lighting.

Before

Lecture hall with old lighting.

After

Lecture hall with newly installed LED lighting.

Buildings:

- Engineering East

- Old Music

- Speech Arts

- Conley Art

- Family & Food Science

- McKee Fisk

- Grosse Industrial Tech

- North Gymnasium

- South Gymnasium

- Downing Planetarium

- Downing Planetarium Museum

- Agricultural Mechanics

- Enology Building

- Viticulture Building

- Library

- WET Incubator

- University Center

- Frank W. Thomas Building

- Kremen Education

- Peters Business

- Warehouse

- Plant Operations

- Agricultural Operations

- Public Safety

Benefits

- $340,000 in incentives from PG&E Commercial Whole Building Performance Program

- Electrical consumption reduced by more than 61%

- Extended life of LED lighting significantly reduces maintenance

- Fewer lamp and ballast replacements reduce operating costs

- Retrofits result in annual savings of 8,646,693 kBtus

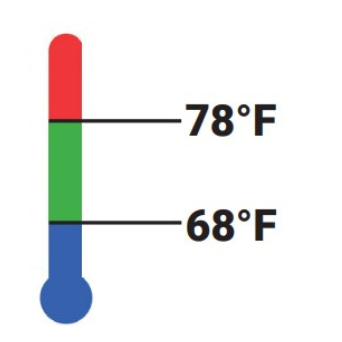

Upgrades were completed on the heating, ventilation, and air condition (HVAC) and energy management systems (EMS) in ten campus buildings. Energy management systems monitor and control the HVAC systems to maintain occupant comfort while increasing energy efficiency. EMS provides real-time feedback which allows for control adjustments to be made and issues to be addressed. All buildings on campus adhere to temperature setpoints of 68-78°F prescribed by California State Executive Orders.

What is zoned heating and cooling?

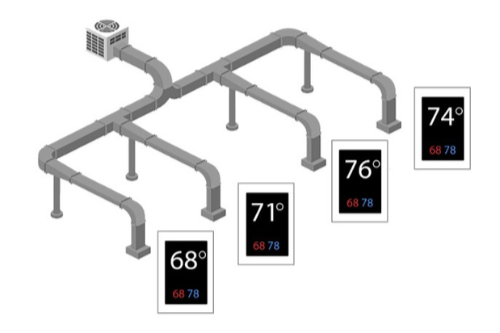

Heating and cooling in the ten buildings function in zones. Zoned HVAC is a method of controlling the temperature of different areas within a building using a single HVAC system. Within the ductwork, there are sensors and dampers that regulate and redirect air to specific areas within each building.

How does it affect me?

Like your house, the HVAC system heats and cools several rooms at once. When one sensor reads a temperature that is outside of the set points, all the rooms will be heated and or cooled. This creates office spaces or classrooms that are warmer or cooler than others while remaining within the bounds of the temperature setpoints of 68-78°F. Sensors are present in every room but cannot be individually controlled.

An example of how zoned heating temperatures can fluctuate from room to room but remain

within the setpoints of 68-78°F.

HVAC and Control Upgrades

The HVAC and EMS upgrades that occurred include:

- 3200 Honeywell control points

- 42 air handling units (AHUs)

- 53 exhaust fan coils

- Over 330 variable air volume boxes

- 18 variable frequency drives on AHU

- Outdoor air damper at Grosse Industrial Tech

The new EMS uses the University's existing fiber network to provide communication between building controls and the monitoring software. In addition to monitoring and controlling equipment in the Central Utility Plant, the new EMS controls:

- Temperature setpoint optimization

- HVAC scheduling

- Discharge air temperature reset

- Outdoor air control

- Economizer control

- Demand-controlled ventilation

- Variable speed drives on air handlers and on pumps

Buildings:

- Old Music

- New Music

- Speech Arts

- Family & Food Science

- McKee Fisk

- Engineering West

- Grosse Industrial Tech

- Engineering East

- Kremen Education

- Peters Business School

- North Gym

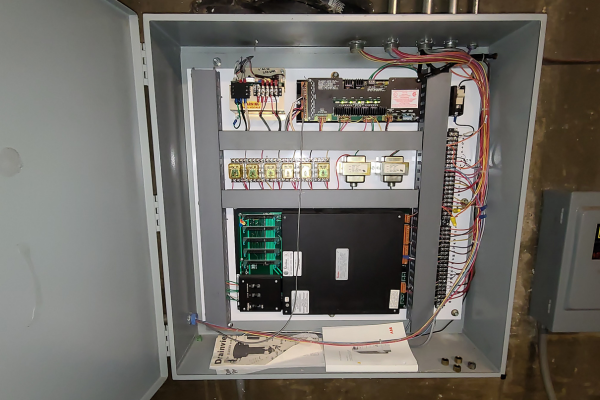

HVAC Control Panel (Before & After)

Before

Old HVAC control panel meters.

Old HVAC control panel internal wiring.

After

The internal wiring of the new HVAC panel.

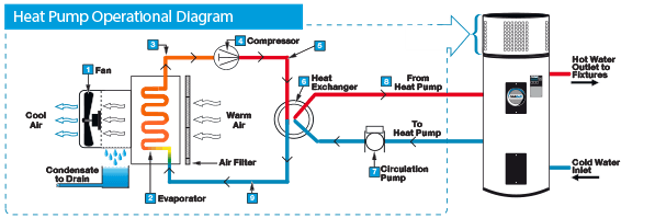

As part of the CUPR project, outdated heating hot water to domestic hot water heat exchangers in 14 campus buildings were removed and replaced. Domestic hot water (DHW) is used for hand washing, showering, labs, etc. Original DHW heat exchangers were replaced with more efficient heat pump water heaters (which use electricity to transfer heat from the air to water) or tankless water heaters in the chiller plant (which provide hot water on demand without the use of a heated water storage tank).

Before

After

Old DHW heat exchangers have been replaced with more efficient heat pump water heaters.

Before

Old DHW heat exchanger

After

New heat pump water heater

After

New tankless water heater

Buildings:

- Speech Arts

- Conley Art

- AG Science

- McLane Hall

- Professional and Human Services

- McKee Fisk

- Social Science

- Grosse Industrial Tech

- North Gym

- South Gym

- Engineering East

- Science 1

- University Center

- Frank Thomas